●

Equipment overview1. Use magic mirror principle to observe micro defects on the surface of wafer mirror samples that cannot be confirmed visually.

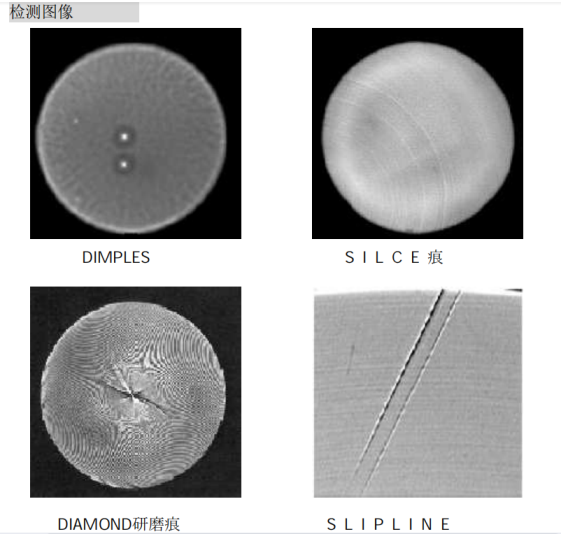

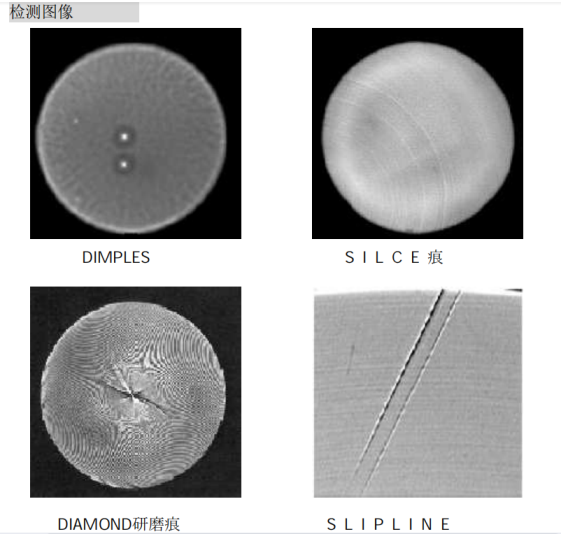

2. Concave defects are brighter and convex defects are darker. The type, location and size of defects shall be determined by light and shade.

3. It can detect dimples, bumps, grinding marks, grinding marks, slip lines, edge defects, warpage, deformation and other abnormalities on the wafer surface.

●

Equipment purposeSilicon wafer surface detection after cutting, grinding, polishing, epitaxy and annealing (for mass production)

. SiC, GaN and other compound wafer surface defect detection

. Surface and internal defect detection of sapphire, crystal and glass wafer

For wafer sampling inspection of various projects (offline)

●

Equipment expertise1. All surface conditions are instantaneous detection

2. Optical system corresponds to Level 1 optical system

3. Maintenance free optical system

4. It can be changed according to the inspection content, detection sensitivity and detection magnification

5. Customize the best optical system according to each sample and inspection position.

●

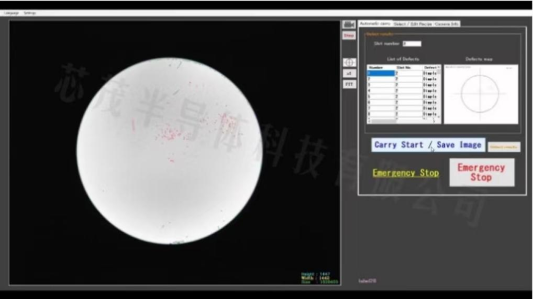

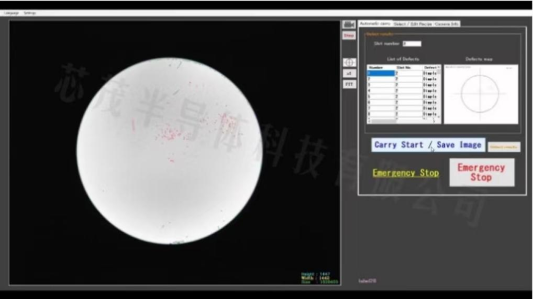

Automatic portrait analysis functionBased on the defect judgment critical value set before detection, the image obtained automatically can be analyzed, the defect type can be judged, the defect position can be visualized, the location coordinates can be calculated, the defect size can be represented, etc.