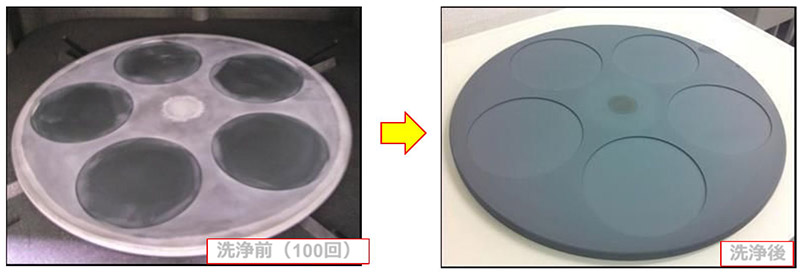

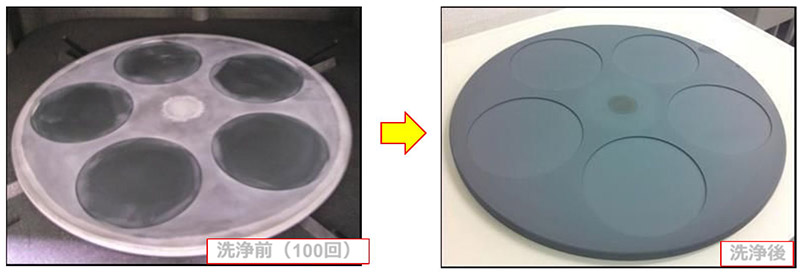

● This equipment is used to remove deposits (GaN, AlN, etc.) attached to MOCVD trays and parts. The dry cleaning method with clean gas is adopted, so the wet post-processing is not required, which can reduce the damage of pallet and parts.

● Dry cleaning with clean gas can reduce the damage to the tray, effectively remove the sediment, and reduce the damage compared with other cleaning methods.

● No subsequent treatment process is required, and no waste liquid treatment is required to improve production efficiency and reduce operating costs.

● After the tray or parts are put into the cleaning furnace by the automatic cleaning system, the cleaning can be started with only one switch operation.

● The corresponding outer diameter is φ 800mm large tray, 6 can be cleaned at the same time.

● Box shaped cavity is adopted to save space and energy.

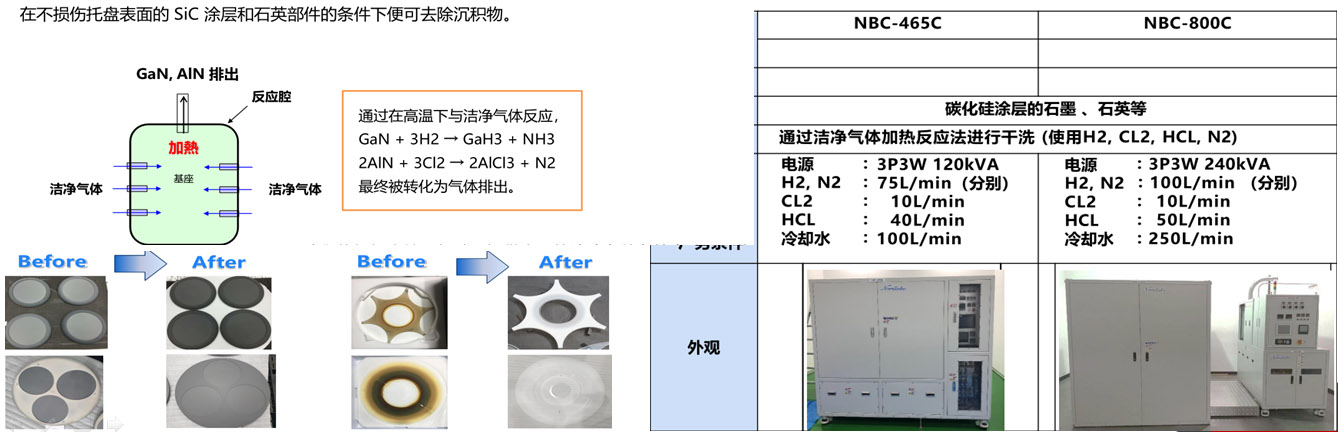

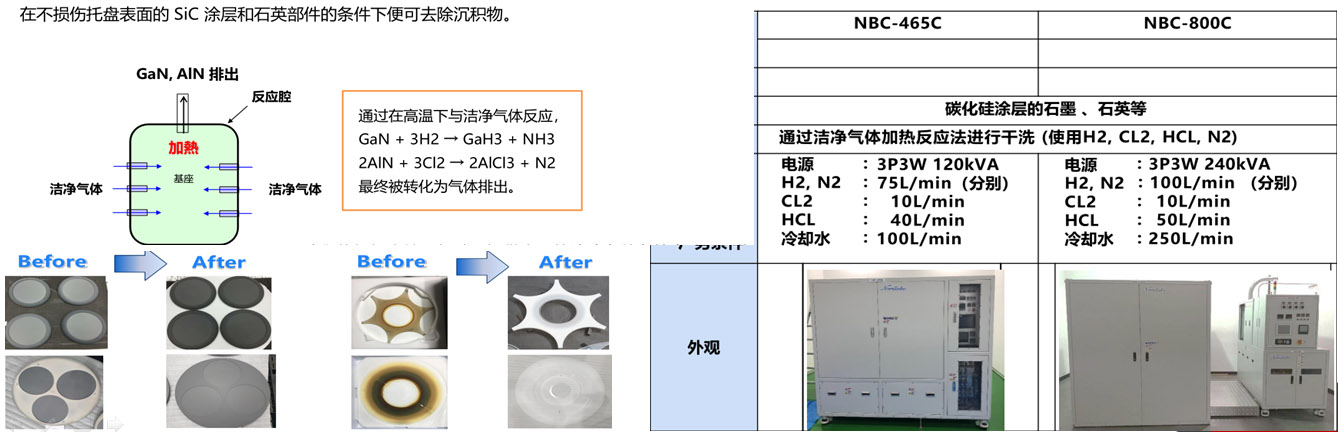

Cleaning principle:Through the reaction of GaN, AlN and other sediments with clean gases such as H2 and CL2 under high temperature, the sediments can be gasified to finally achieve the purpose of removal.

Equipment advantages:① Dry cleaning with clean gas can reduce the damage to the tray, effectively remove the sediment, and reduce the damage compared with other cleaning methods.

② There is no need for subsequent treatment process and waste liquid treatment. Improve productivity and reduce operating costs.

③ Fully automatic cleaning system, after the tray or parts are put into the cleaning furnace, only one switch operation is required to start cleaning.

④ It can correspond to large pallet, and the corresponding outer diameter is φ 800mm tray, 6 can be cleaned at the same time.

⑤ The space saving design adopts box shaped cavity to save space and energy.

⑥ A worldwide cleaner with a variety of process gases, such as Cl2, HCl, H2, N2